Phenolic countertops pros and cons

Phenolic countertops pros and cons area frequently discussed topic, and below we’ll explore its advantages and disadvantages.

Pros

- Resistant to conventional chemical reagents, suitable for basic experimental needs.

- Dense surface for easy cleaning—stains wipe off quickly, with low maintenance costs

- High cost-performance, priced lower than high-end materials like epoxy resin.

Cons

- Average scratch resistance, prone to scratches from sharp instruments with long-term use.

- Limited high-temperature resistance, cannot directly contact high-temperature utensils.

- Requires splicing during installation, and joints may pose contamination risks.

Feature

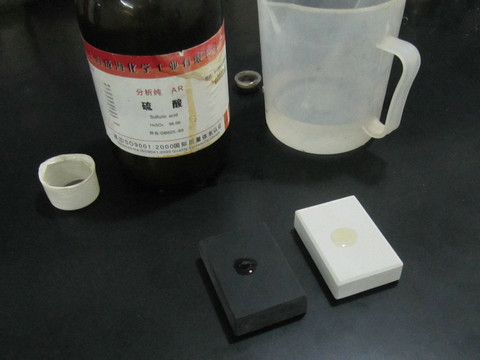

Chemical resistance: These boards have excellent chemical resistance. Their dense surfaces can withstand sulfuric acid and sodium hydroxide.

They are ideal for laboratories and medical workstations. Their high-pressure structure gives them strength.

Resistant Impact: They are resistant to impact.They are flame-retardant. They can tolerate short-term temperatures of 130°C. This balances safety and

cost-effectiveness.

Temperatures resistance:They will soften at temperatures above 180°C.

Moisture resistance:There are challenges in sealing joints for large areas. Sunlight and moisture may cause them to fade or swell.

Phenolic resin worktops Specification

| Phenolic resin countertops | Low cost |

|---|---|

| Material | Phenolic resin |

| Size | As required |

| Thickness | 12.7 |

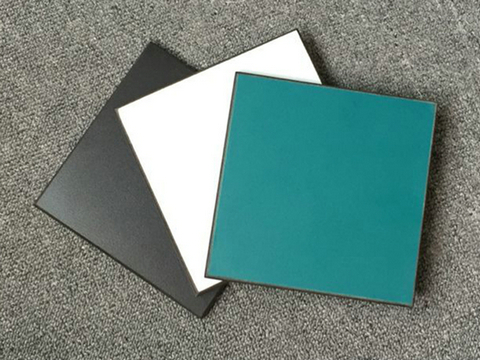

| Color | Black,grey,white |

| Surface finish | Matt |

| Density | 1.51 |

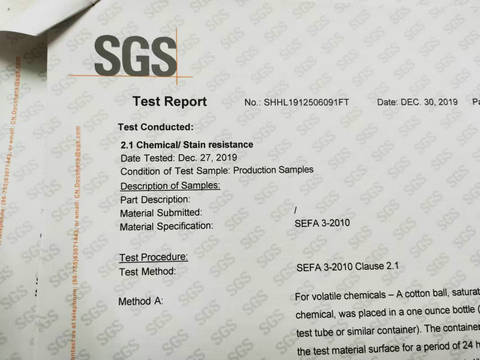

| SGS certificate | SEFA3-2010 |

| Mini order | 30 |

| Fabricating drawing | Requred |

chemical resistance

SGS certificate

a professional Phenolic resin countertops supplier