Epoxy Marine edge worktops

- Epoxy marine edge worktops, that is, epoxy water-proof edge worktop, is a “water-proof expert” in laboratory furniture. There are many places where water is used in the laboratory. Whether it is cleaning instruments, preparing solutions, or processing samples, water will inevitably spill out. With such a worktop with a water-proof edge, there is no need to worry about water flowing down the worktop into the cabinet and damaging the furniture. Today, let’s talk about its applications in laboratory furniture and see how practical it is.

Feature

- Epoxy marine edge worktops are specialized edge solutions for lab furniture, combining epoxy resin’s chemical resilience with marine-grade structural integrity.

- They excel in harsh lab environments—resisting acids, solvents, and constant cleaning.

- Engineered to shield lab countertops (epoxy, phenolic, ceramic) from impact, spills, and edge chipping.

- Available in a wide range of specifications, sizes, and colors to meet the diverse needs of different laboratory furniture.

Application

Washing Tables

The washing table in the laboratory is even more inseparable from epoxy marine edge worktops. The washing table is a place specially used for cleaning instruments. It deals with water every day, and sometimes high-pressure water guns are used for flushing, with large water flow and strong impact. If an ordinary worktop is used, the water would have flowed everywhere along the edge, and the cabinet under the washing table would definitely suffer. But with this kind of worktop with a water-proof edge, the situation is quite different. The raised edge can block most of the water. Even if a small amount of water overflows the edge, the connection between the edge of the worktop and the cabinet is sealed, so water cannot seep in.

Fume Hoods

The figure of epoxy marine edge worktops can also be seen in the fume hood of the laboratory. Sometimes, experiments that require water are carried out in the fume hood, such as reflux condensation and water bath heating. Water in the condenser tube may drip onto the worktop, or water may be accidentally spilled during operation. The cabinet under the fume hood usually contains some accessories of precision instruments and spare reagents. If water gets in, it will be a big trouble. With a worktop with a water-proof edge, water can be blocked on the worktop and flow away along the special drainage outlet without seeping into the cabinet.

Epoxy marine edge countertops specification

| Epoxy marine edge worktops | Wash cabinet and fume hood worktops |

|---|---|

| Feature | Chemical resistant, super length ,easy installation |

| Material | Epoxy resin |

| Type1 | EDG12.7 |

| Size | 3200/18/30 mm |

| Application | Designed for 12.7 mm thick phenolic resin boards, solving the water blocking problem of the phenolic laminate countertop |

| Type2 | EDG20 |

| Size | 3200×25/30 mm |

| Application | Suitable for edge sealing and water blocking of phenolic laminate boards, epoxy boards and ceramic boards with a thickness of 20 mm. |

| Type3 | EDG15 |

| Size | 3200×20/30 mm |

| Application | Suitable for edge sealing and water blocking of phenolic laminate boards, epoxy boards and ceramic boards with a thickness of 15 mm |

| Colors | Black,Grey, White |

| Height of the raised part for water retaining | 5 mm |

Edge section details

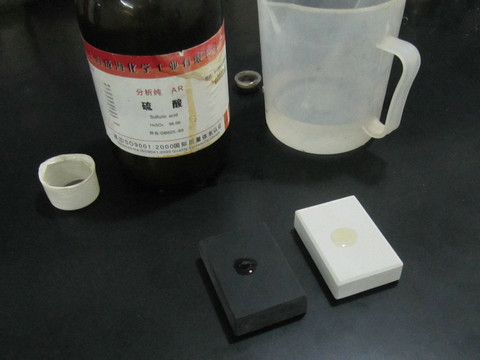

Epoxy marine edge worktops section sample

Marine edge products

Epoxy marine edge worktops project

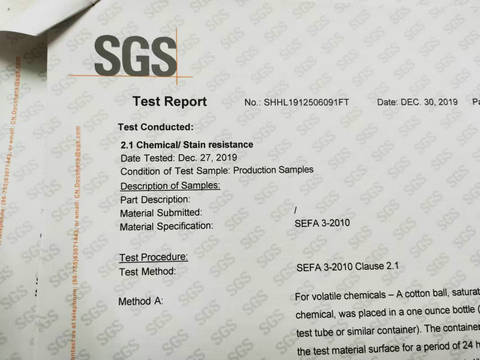

Certificate

Export packing

Shipping

A professional epoxy marine edge worktops supplier