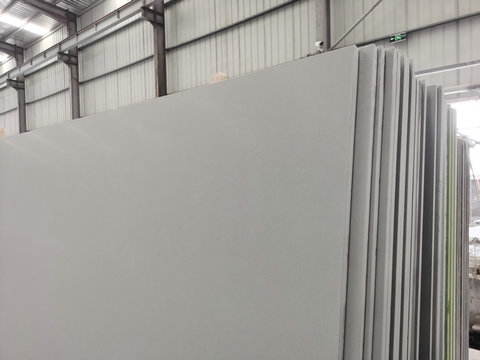

Epoxy work surfaces

In general, the many advantages of Epoxy work surfaces are inseparable from its production process.From the selection of raw materials to each step of processing, efforts must be made.It is precisely because of the rigor and attention to detail in production that such a practical worktop can be created.If your place needs to replace the worktop, you might as well consider the epoxy one; it will definitely be a great help.

Main raw materials for production

- First, let’s talk about the epoxy work surfaces raw materials needed to produce this thing.

- The main ones are epoxy resin and curing agent; these two are the core.

- Epoxy resin is like glue, which can stick various things together and is quite strong itself.

- The curing agent, like a catalyst, can turn epoxy resin from liquid to solid, making it hard.

- In addition to these two, sometimes fillers like quartz sand and glass fiber are added. With these, the epoxy work surfaces will be more wear-resistant and pressure-resistant.

- There are also pigments, which are used to give the worktop different colors. However, most of those used in laboratories are light-colored, looking clean.

Specific Production Process

- What’s the epoxy work surfaces production process like? It’s not too complicated to say, but every step must be careful.

- First is batching. Epoxy resin, curing agent, fillers, pigments, etc., must be mixed in a certain proportion. The proportion is crucial; a little more or less won’t work.

- For example, if too little curing agent is added, the epoxy resin won’t cure completely, and the worktop will be soft and not strong. If too much is added, it may cure too quickly and harden before processing, which is a waste of effort.

- When batching, a special mixing machine must be used to stir these materials evenly, like stirring batter, without any lumps. Otherwise, the produced epoxy work surface will have small bubbles or hard lumps, affecting quality.

Pouring and Initial Shaping

- The next step for the stirred material is pouring.

- A mold is needed, and the shape of the mold is the shape of the epoxy work surface , usually rectangular, and the size can also be determined according to needs. Pour the stirred epoxy material into the mold. Pour slowly to avoid bubbles. After filling, use a tool to smooth the surface so that the material is evenly distributed in the mold.

- At this time, a vibrating machine can also be used to vibrate the mold to shake out the small bubbles inside. Otherwise, if there are bubbles in the worktop, it will be easy to break during use.

Key Points in the Curing Process of epoxy work surface

- Next is curing.

- Put the mold with the epoxy material in a suitable environment. The temperature should not be too low or too high, usually between 20 and 30 degrees Celsius.

- If the temperature is too low, curing will be slow and delay time. If the temperature is too high, curing will be too fast, which may generate stress and cause the worktop to crack.

- During the curing process, the epoxy material will gradually harden. This process takes about a few hours, and sometimes more complex ones may take a day. During this period, the mold must not be touched casually, otherwise the epoxy work surface will be deformed.

Post-release processing

- After curing, it can be demolded, and the worktop can be taken out of the mold.

- The newly taken out worktop is not finished yet. The surface may be a bit rough, and the edges are not neat, so it needs to be processed. Use sandpaper to smooth the surface and round the edges to avoid cutting hands. If there are special requirements, such as drilling a hole in the worktop to place instruments, it can also be processed at this time. After polishing, it must be cleaned to wipe off the dust, otherwise it will affect subsequent use.

Advantages of epoxy work surfaces

- Why is this epoxy worktop good?

- You can see from the production. Think about it, with precise raw material proportioning, uniform stirring, proper curing, and careful processing, can the product be bad? It has high hardness. Scratching it with a hard object basically leaves no trace, which is largely related to the fillers added.

- Moreover, its surface is very smooth, not easy to hide dirt, and easy to clean. Just wipe it with a cloth, which is very important in laboratories and factories, making it easy to maintain hygiene.

Corrosion resistance and temperature stability

- Its corrosion resistance is also due to the production process.

- Epoxy resin itself is not easy to be corroded by chemical reagents. Coupled with the special coating on the surface, even if some acid or alkali is spilled, as long as it is wiped off in time, there is basically no problem.

- Once in a factory, I saw a worker accidentally spill oil on the epoxy worktop. He was busy working and didn’t wipe it off. After half a day, when he wiped it, there was no trace left, and it was still clean.

- In terms of temperature changes, it is also very stable. The temperature in the workshop is high in summer, and sometimes the heating is turned on in winter. It will not expand and contract as much as some worktops, and will not crack or deform. This is because during production and curing, it has been tested by temperature, and its internal structure is relatively stable.

Notes in production

- However, there are some things to pay attention to during production.

- For example, when batching, it must be in accordance with the standards, and the proportion cannot be changed casually for convenience. In addition, stirring must be thorough, otherwise there will be unstir well particles inside, which will affect the strength of the worktop.

- The curing environment must also be controlled, with appropriate temperature and humidity, otherwise it is easy to produce defective products.

Flexibility and efficiency of production

- Now many places are willing to use epoxy worktops.

- In addition to being easy to use, the production is also relatively flexible. Any size or color can basically be met.

- Moreover, the production cycle is not too long, unlike some materials that take a long time to make.

- When mass-producing, the efficiency is also very high, which can meet the needs of many factories and laboratories.