Lab ceramic worktops

In general, lab ceramic worktops are really easy to use in the laboratory.They are corrosion-resistant, high-temperature resistant, wear-resistant, easy to clean, and durable.Whether it’s a chemical laboratory, a biological laboratory, or other places that need an operating table, it’s very suitable to use.If your laboratory is planning to replace the worktop, you might as well consider this kind of ceramic worktop. It will definitely not disappoint you.

Feature

Its Appearance

- First, let’s talk about its appearance. This worktop is usually clean and white, looking very fresh. The surface is smooth, and it feels very slick, unlike some worktops that are bumpy. What’s more, there are many color options. Besides the common white, there are light gray, beige, etc., which can match the style of different laboratories. The size is also flexible and can be customized according to the size of the laboratory. Whether it’s a small corner operating table or a long table, it can be made to fit perfectly.

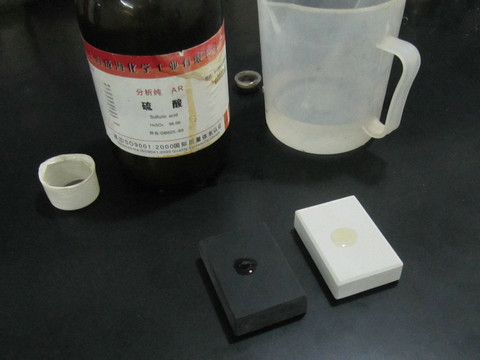

- Then, let’s talk about its performance, which is the most important part. In particular, lab ceramic worktops have super strong corrosion resistance, and it’s simply a “chemical nemesis” in the laboratory. There are all kinds of chemical reagents in the laboratory, acidic, alkaline, corrosive ones. It’s common to accidentally spill them on the worktop, but this worktop doesn’t care at all.

Resistance to Strong Acids

- Take strong acids, like hydrochloric acid and sulfuric acid.

- Sometimes, when pouring, you might shake your hand and spill a little, and it drips on the worktop and you don’t get to wipe it off for a long time. Guess what? There’s no change at all. It doesn’t bubble, and it doesn’t leave a mark. Just rinse it with water and it’s like nothing happened.

- Once, during an experiment, a colleague accidentally spilled a small area of nitric acid with a not low concentration. He was in a hurry to deal with other things at that time and forgot to wipe it off for almost half an hour. As a result, the worktop was still smooth. If it were another worktop, it would probably have been corroded into small pits.

Resistance to Strong Alkalis

- Strong alkalis can’t do anything to it either.

- Like sodium hydroxide solution, sometimes you forget to cover the lid after preparing the reagent, and the solution flows down the bottle wall onto the worktop and stays there for most of the day.

- Wipe it with a cloth and it’s still clean. It won’t swell and deform like a wooden worktop, nor will it get sticky due to corrosion like an ordinary plastic worktop.

Resistance to Organic Solvents

- There are also some corrosive organic solvents, such as alcohol and acetone. Occasionally, they are spilled on it. No matter how long they stay, the worktop remains the same.

- It won’t change color, nor will it crack or peel. Once, when organizing the reagent rack, a bottle of alcohol was not placed stably and fell over, spilling a small puddle on the worktop. When it was found, it was almost dry. After wiping, there was no trace at all. It’s really reassuring.

High-Temperature Resistance

- In addition to corrosion resistance, it’s also very resistant to high temperatures.

- Sometimes, in experiments, you need to heat things with an alcohol lamp, and accidentally put a hot beaker on the worktop, you don’t have to worry about leaving a burn mark.

- Once, a new intern put a heated test tube directly on it. At that time, everyone was on tenterhooks, but when it was picked up, the worktop was fine. The quality is really excellent.

Wear Resistance

- Wear resistance is also one of its major advantages.

- In the laboratory, various instruments and glassware are placed every day, and when they are moved around, the worktop is not easy to be scratched. A worktop that has been used for several years still looks almost new. This is better than many materials.

Easy to Clean

- Cleaning is also very easy.

- Because the surface is smooth, whether it’s spilled potion or dust, just wipe it with a wet cloth and it’s clean. Sometimes, if you accidentally get some oil stains, pour a little detergent, wipe it a little, and it will return to its original state without much effort. Unlike some worktops, where stains seep in and are hard to clean, and they can breed bacteria, which is a big problem in the laboratory. The ceramic worktop doesn’t have this trouble.

Long Service Life

- Lab ceramic worktops also have a long service life.

- As long as you pay a little attention at ordinary times and don’t hit it hard with very hard things, it can last for ten or eight years. It’s actually quite cost-effective. You don’t have to change the worktop often, saving a lot of trouble and money.

Points to Note

- However, there’s one thing to note.

- Although this worktop is strong, it’s afraid of violent collisions. If you hit it hard with a hammer or other hard things, it may crack. So, it’s always a good idea to be gentle when placing or moving things on it.

Light blue lab ceramic worktops

Black marine edge lab ceramic countertop boards

A professional lab ceramic worktops supplier